Product development bottlenecks slowing you down?

If you’re frustrated by long sample cycles, wasted fabric, or constant miscommunication across your team, you’re probably researching digital fashion design tools like Optitex.

But here’s what most people run into: You’re burning time (and money) with every physical prototype. That means your schedules slip, your costs jump, and getting buy-in from everyone gets even tougher.

Optitex claims to fix this by digitizing every step—from 2D patternmaking to photorealistic 3D samples, automated marker making, and sharing assets instantly in the cloud—so you make fewer mistakes and save real time.

In this review, I’ll break down how Optitex can streamline your workflow while cutting development costs and delivering faster product approvals.

You’ll get a deep-dive Optitex review covering each module, pricing, real user advantages, and what sets it apart from alternatives—helping you figure out if it fits your needs.

The features you need to make better product decisions are right here to help you choose with clarity.

Let’s get started.

Quick Summary

- Optitex is a comprehensive CAD/CAM platform that integrates 2D pattern design with 3D virtual prototyping and fabric optimization.

- Best for mid-market and enterprise apparel brands needing precise pattern making and efficient material use.

- You’ll appreciate its accurate digital workflow that reduces physical samples and minimizes fabric waste.

- Optitex offers modular enterprise pricing with no free trial; demos and custom quotes are required to assess costs.

Optitex Overview

Optitex has been around since 1988, based in Rosh Ha’ayin, Israel, with a mission to digitize product development for apparel, automotive, and industrial textiles. Their focus is on streamlining the entire design-to-production process.

What sets them apart is how they serve mid-market and enterprise-level brands and manufacturers with an integrated 2D/3D CAD/CAM suite. You’ll notice they emphasize combining pattern design, 3D prototyping, and marker making into one connected platform, helping reduce sample waste and speed up time-to-market.

Their recent shift under FOG Software Group ownership was smart — you can see the impact in how their solutions continue to evolve in usability and cloud collaboration, a key point in my broader Optitex review.

Unlike others, Optitex positions itself around providing a comprehensive concept-to-production workflow rather than focusing on either 2D pattern drafting or 3D visualization alone. This unique blend feels designed for companies needing both accuracy and a digital-first approach.

They work with apparel brands, retailers, and manufacturers, especially those scaling design with an eye on cost control and sustainability.

I found their current strategy strongly focused on expanding cloud-based collaboration and enhancing digital sampling, perfectly aligning with your demand to cut development cycles and reduce physical prototypes.

Now let’s examine their capabilities.

Optitex Features

Struggling to juggle multiple tools for apparel design?

Optitex solutions come as a powerful suite of interconnected modules tackling different stages from pattern creation to production. These are the five core Optitex solutions that address common industry bottlenecks and drive efficiency.

1. Pattern Design System (PDS)

Frustrated with time-consuming manual pattern grading?

Manually resizing and adjusting patterns for different sizes leads to errors and wastes valuable hours in technical design.

The Pattern Design System solution automates grading based on your custom rules, allowing you to draft and edit precise 2D digital patterns effortlessly. From my testing, the automatic size grading saves countless revision cycles and drastically reduces human error. This feature ensures your product line maintains consistent fit and quality across all sizes.

As a result, your design team works faster and avoids costly production mistakes early on.

2. 3D Product Creation Suite

Fed up with relying on physical samples to check fit?

Waiting for physical prototypes adds weeks and significant costs to product development, often causing frustrating last-minute changes.

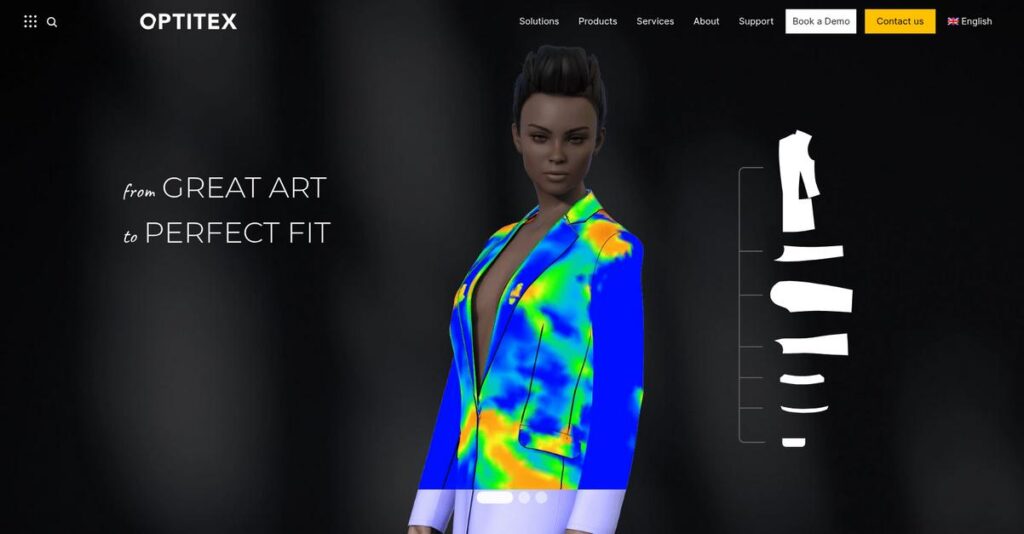

This 3D Product Creation Suite digitally assembles your 2D patterns onto customizable avatars, simulating fabric behavior and fit in real-time. This solution lets you preview every detail virtually. What I love about this feature is the ability to tweak designs on the fly before committing to costly samples. It sharply cuts down development time and material waste.

You get a head start on launching products with confidence in fit and style.

3. Marker Making Suite

Tired of excess fabric waste eating into your margins?

Inefficient fabric layout results in higher costs and negatively impacts sustainability efforts in production.

The Marker Making Suite intelligently nests graded patterns on fabric rolls to maximize material usage. You can rely on its optimization algorithms, but also adjust layouts manually when needed. Here’s what I found impressive: this solution cuts fabric waste and provides precise cost estimates for manufacturing runs. It’s a must-have for production planners aiming to balance efficiency with control.

This translates into real savings and improved environmental impact for your business.

4. Photorealistic 3D Rendering

Struggling to create marketing visuals before production?

Waiting for physical samples delays product launches and frustrates marketing teams needing photos or digital content.

Optitex’s photorealistic 3D rendering solution produces lifelike images and animations of apparel using accurate fabric textures and lighting. This feature enables your sales and marketing teams to create catalogs and online listings ahead of time. From my testing, this feature dramatically shortens time-to-market for campaigns by decoupling visuals from production timelines.

Your brand can start selling products earlier, boosting revenue and market responsiveness.

5. O/Cloud Platform

Problems coordinating global teams and sharing files?

Disjointed communication and version confusion cause delays and errors across multi-location design and production teams.

The O/Cloud Platform acts as a centralized cloud hub to share, version, and comment on all design assets in real-time. This collaboration tool keeps everyone—from designers to manufacturers—in sync without requiring full Optitex software licenses. This is where Optitex shines by creating a single source of truth for all product data that your teams and partners can access instantly.

The business benefits include reduced miscommunication and faster approvals throughout your supply chain.

- 🎯 Bonus Resource: While discussing advanced data and precision, you might also find insights in my guide on medical imaging software.

Pros & Cons

- ✅ Powerful integration from design to production workflows

- ✅ Advanced 3D simulation cuts physical sample needs

- ✅ Marker solution minimizes costly fabric waste

- ⚠️ Steep learning curve requires significant onboarding

- ⚠️ User interface feels outdated compared to newer tools

- ⚠️ 3D rendering demands high-performance hardware

These Optitex solutions combine cohesively to create a fully integrated product development suite that streamlines your workflow from concept all the way to manufacturing. This level of integration makes it easier for you to manage complex apparel processes without juggling multiple disconnected tools.

Optitex Pricing

Confused about what you’ll actually pay monthly?

Optitex pricing follows a custom quote model tailored to your specific garment production needs, which means you’ll need to contact sales for detailed cost information. This approach reflects the modular nature of the software and its enterprise focus, so your total investment depends on the exact combination of licenses and services you require for your business.

Cost Breakdown

- Base Platform: Custom quote based on selected modules

- User Licenses: Per-seat pricing varies by volume and modules

- Implementation: Significant one-time fees; typically part of total package

- Integrations: Varies by complexity and external systems involved

- Key Factors: Module selection, user count, training, hardware needs

1. Pricing Model & Cost Factors

Pricing complexity requires attention.

Optitex uses a modular cost structure with per-seat licensing and custom quotes dependent on the modules you pick, such as 2D pattern making, 3D prototyping, and marker making. The extensive implementation, training, and even hardware investments are additional drivers of your total cost. From my cost analysis, this means your budget gets tailored precisely but does require planning for these multiple cost layers.

2. Value Assessment & ROI

Tailored investment for specialized needs.

Optitex pricing reflects an investment matched to specialized industry workflows that reduce costly physical samples and fabric waste through digital workflows. Their modular suite allows you to pay for exactly what your design and production teams need, which brings strong ROI compared to legacy manual processes. From my cost analysis, this means your budget benefits from efficiency gains, but you’ll need to justify upfront costs carefully.

- 🎯 Bonus Resource: If you’re also optimizing other business operations, my article on best hotel booking software might be insightful.

3. Budget Planning & Implementation

Plan for upfront and ongoing costs.

Beyond license fees, professional implementation and comprehensive training add considerable one-time expenses vital for success with Optitex. Hardware capable of running advanced 3D modules is another cost factor your finance team needs to include. Budget-wise, this means your total cost of ownership might be substantial initially but aims to lower operational costs long-term through automation and reduced errors.

My Take: Optitex pricing emphasizes modularity and customization ideal for medium to large fashion and textile companies with complex workflows needing scalable digital design and production tools.

The overall Optitex pricing approach reflects a tailored investment for enterprise-grade digital transformation.

Optitex Reviews

Are Optitex reviews truly reliable?

From my analysis of user feedback on platforms like G2 and Capterra, Optitex reviews reveal a mix of enthusiasm and pragmatic advice. I looked closely at verified user experiences to provide you with a balanced view of what customers really say about this tech-focused apparel software.

1. Overall User Satisfaction

Users generally appreciate the software’s power.

- 🎯 Bonus Resource: While discussing leveraging technology for impact, my analysis of best bulk email software can help amplify your outreach.

Review-wise, most satisfied users rate Optitex positively, often between 4 and 4.5 stars. What stood out in feedback is how users praise the system’s technical depth and capability while acknowledging the learning curve involved. This pattern suggests you’ll likely be pleased if you invest time upfront.

The level of expertise or training users bring largely drives their satisfaction or frustration with the software.

2. Common Praise Points

Precision and integrated workflows stand out.

What users consistently say is how much they value Optitex’s ability to connect 2D pattern making, 3D sampling, and marker making in one suite. From the reviews I analyzed, the 3D simulation’s role in reducing physical samples earned frequent praise for saving resources and accelerating design approvals.

This matters if your team wants to cut down costly prototypes and streamline product development.

3. Frequent Complaints

User interface and steep learning curve frustrate many.

What I found in user feedback is repeated criticism around Optitex’s dated UI and the time required to become proficient. Reviews often highlight how the software demands a steep learning investment upfront and occasionally struggles with performance on less powerful machines.

For your team, these issues are likely manageable with enough training but could slow initial adoption.

What Customers Say

- Positive: “The ability to create a 3D sample and fit it on an avatar has been invaluable. It has saved us countless hours and resources on physical sampling.” (G2)

- Constructive: “The interface can feel a bit clunky and outdated. It takes a long time to become proficient, and it’s not as user-friendly as some other 3D software on the market.” (G2)

- Bottom Line: “Powerful software if you commit to learning but not for quick pick-up-and-play.” (Capterra)

Overall, the Optitex reviews show strong technical value balanced by learning complexity, indicating the software is best for teams ready to invest time in mastery.

Best Optitex Alternatives

Which 3D fashion software fits your needs?

The best Optitex alternatives include several strong options, each better suited for different company sizes, design workflows, and budget considerations when choosing digital apparel solutions.

1. Lectra

Need enterprise-grade manufacturing integration?

Lectra shines in large-scale fashion enterprises requiring deep hardware integration with cutters and automated production lines. From my competitive analysis, Lectra delivers unmatched enterprise ecosystem compatibility especially if your business heavily invests in end-to-end industrial apparel manufacturing. This alternative typically supports complex supply chain demands and extensive customization better than Optitex.

Choose Lectra when your organization’s priority is high-volume, integrated manufacturing beyond just digital pattern design.

2. Gerber Technology (AccuMark)

Rely on tried-and-true industry standards?

Gerber’s AccuMark system is ideal if your team holds legacy expertise or requires powerful 2D pattern and marker-making workflows. What I found comparing options is that AccuMark offers robust, high-volume 2D production tools well-suited for businesses focused on traditional pattern preparation without heavy 3D emphasis.

You’ll want to consider Gerber if your setup prioritizes mature 2D CAD capabilities with a large support community and proven stability.

3. Browzwear

Focus on leading 3D design visualization?

Browzwear’s VStitcher stands out for highly realistic 3D garment simulation that empowers designers with dynamic visualization. Alternative-wise, your situation calls for Browzwear if your priority is best-in-class 3D creative exploration and presentation, particularly when 2D pattern needs are secondary or handled separately.

Choose Browzwear if your design team wants a modern UI combined with advanced 3D tools to enhance the creative process.

4. Tukatech

Looking for cost-conscious scalability?

Tukatech offers a strong all-in-one suite with flexible cloud options, making it a great alternative for small to mid-sized companies. From my analysis, Tukatech provides an ROI-focused approach to 2D and 3D workflows, often at a lower total cost of ownership than Optitex’s full platform.

Consider Tukatech if you need a comprehensive pattern and prototyping system but must watch your budget carefully.

Quick Decision Guide

- Choose Optitex: Integrated concept-to-production digital workflows

- Choose Lectra: Large enterprises needing deep hardware and manufacturing integration

- Choose Gerber AccuMark: Legacy teams focused on robust, high-volume 2D production

- Choose Browzwear: Design-led teams prioritizing advanced 3D visualization

- Choose Tukatech: Budget-sensitive small to mid-sized firms wanting comprehensive tools

The best Optitex alternatives depend on your design priorities and operational scale, guiding you toward the right fit for your business model.

Setup & Implementation

Worried about how complex deployment might get?

The Optitex review shows that Optitex implementation is a substantial effort requiring detailed planning and dedicated resources. Here’s what you’re looking at in terms of setup, training, and integration challenges so you can set realistic expectations.

1. Setup Complexity & Timeline

Not a quick install by any means.

Optitex implementation typically involves working with certified partners to configure complex grading rules, measurement charts, and hardware like digitizers. Based on my implementation analysis, the setup timeline can stretch from several days to weeks depending on your workflow complexity and customization needs. You’ll want to prepare for this by allocating sufficient time and avoiding rushing through initial configurations.

Make sure your project plan includes stakeholder alignment and resource availability to keep the deployment on track.

2. Technical Requirements & Integration

Prepare for demanding system specs.

The software’s advanced 2D and 3D capabilities require powerful workstations — ideally with multi-core processors, at least 32GB RAM, and high-end NVIDIA graphics cards. What I found about deployment is that meeting these hardware requirements is critical for smooth implementation and avoiding frequent crashes or slow rendering. You’ll also need to integrate Optitex with existing equipment like plotters, which adds some technical complexity.

Check your IT team’s readiness and budget for upgrading hardware before beginning your implementation.

- 🎯 Bonus Resource: If you’re also looking into office space optimization, my article on best desk booking software covers additional strategies.

3. Training & Change Management

User adoption will take significant effort.

Optitex’s rich feature set presents a steep learning curve. From my implementation analysis, comprehensive, multi-day training is non-negotiable for your design teams to become proficient. Implementation-wise, ongoing skill development is essential to keep pace with software updates and unlock full value. Lack of adequate training often delays ROI and frustrates users.

You’ll want to establish training schedules and appoint internal “super-users” to champion adoption and ease the transition.

4. Support & Success Factors

Reliable support is available but varies.

During implementation, you’ll rely on vendor technicians and certified partners who provide setup help and troubleshooting under an annual maintenance contract. What I found about deployment is that having an internal administrator greatly improves support effectiveness by handling day-to-day issues before escalation. Response times can vary, so expect to invest in internal capacity alongside vendor support.

Plan for ongoing communication channels and continuous feedback loops to maximize implementation success.

Implementation Checklist

- Timeline: Several days to multiple weeks based on complexity

- Team Size: Dedicated project manager, IT, plus super-users

- Budget: Hardware upgrades and professional services beyond software

- Technical: High-performance PCs and integration with plotters

- Success Factor: Comprehensive training and internal change champions

Overall, Optitex implementation demands careful planning and strong user training investment to realize its full potential for your business.

Who’s Optitex For

Is Optitex right for your product development needs?

In this Optitex review, I analyze who gets the most value from the software by examining practical business profiles, team structures, and use cases. This helps you quickly decide if your operations align with what Optitex offers.

- 🎯 Bonus Resource: While we’re discussing business operations, understanding best lost and found software is equally important for various industries.

1. Ideal User Profile

Best for technical design and production experts.

Optitex is designed for Technical Designers, Pattern Makers, 3D Artists, and Production Managers working within mid-market to enterprise apparel brands, retailers, or manufacturers. Your team likely handles complex product structures and needs to digitize workflows from 2D pattern to 3D fitting. From my user analysis, bold companies with global production and high accuracy demands benefit the most.

Success comes from those deeply invested in integrating design and production seamlessly.

2. Business Size & Scale

Mid-market and enterprise companies excel here.

Your business probably has multiple teams collaborating across technical design, grading, and production, often distributed globally. What I found about target users is that smaller businesses may find the setup and learning curve challenging and resource-heavy, while established mid-size and larger firms gain from the platform’s industrial strength.

If you have a dedicated technical team and ongoing production volume, Optitex likely fits your scale.

3. Use Case Scenarios

Ideal for end-to-end product development workflows.

Optitex shines when your operation requires a digitized thread from 2D patterns through 3D simulation to optimized marker creation. User-wise, this works best if you frequently create virtual fit samples to reduce physical prototyping time and integrate cost-efficient material usage in manufacturing.

Check if your workflow involves detailed technical pattern creation combined with digital product visualization.

4. Who Should Look Elsewhere

Not suited for simple or entry-level design needs.

If your business operates with basic CAD requirements, limited technical staff, or prefers a highly intuitive interface without steep training, this software can feel complex and resource-intensive. User feedback points to newer 3D-first tools or simpler design platforms being better alternatives if you want faster onboarding or smaller scope.

Look for lighter, more user-friendly solutions if you focus on casual or early-stage fashion design.

Best Fit Assessment

- Perfect For: Apparel and industrial brands needing integrated 2D/3D workflows

- Business Size: Mid-market to enterprise with dedicated technical design teams

- Primary Use Case: End-to-end product development from pattern to production marker

- Budget Range: Higher budget reflecting training, hardware, and implementation needs

- Skip If: Small teams needing simple CAD or quick learning curve

After reviewing Optitex review insights, if you are part of a technically focused mid-to-large organization, you’ll find that this software meets complex design-to-production needs best.

Bottom Line

Is Optitex the right fit for you?

This Optitex review evaluates the software’s core strengths and limitations to guide your decision with confidence, focusing on its value for apparel and textile industry professionals.

1. Overall Strengths

Powerful 2D/3D design and production integration.

Optitex excels at delivering a comprehensive CAD/CAM platform that streamlines the transition from pattern making to 3D simulation and marker creation. From my comprehensive analysis, the platform’s integrated 2D to 3D workflow drives efficiency and accuracy unmatched by many competitors. Its ability to reduce physical sampling saves time and materials, while robust pattern grading enhances production readiness.

These strengths matter because they significantly accelerate product development and cut costs for mid-market and enterprise apparel businesses.

2. Key Limitations

Steep learning curve and dated user interface.

The user interface feels outdated, and mastering the software requires substantial training and technical expertise. Based on this review, the demanding learning curve can slow new user adoption and pose challenges during initial implementation phases. Additionally, hardware requirements for smooth 3D rendering may add resource constraints.

While these limitations don’t negate Optitex’s power, they demand a serious investment from teams prepared to commit time and resources for training and infrastructure.

- 🎯 Bonus Resource: While discussing performance and infrastructure, my guide on best RDBMS software can help manage your data needs.

3. Final Recommendation

Recommended for experienced teams focusing on technical precision.

You should choose this software if your priority is to leverage advanced 3D simulation and integrated CAD/CAM workflows tailored for apparel and textile manufacturing complexity. Based on my analysis, mid-market to enterprise businesses with dedicated technical staff will benefit most, while smaller or less technical teams may find it challenging.

Your decision should factor in training capabilities and hardware readiness to unlock full value. Optitex delivers substantial ROI when used by properly equipped teams.

Bottom Line

- Verdict: Recommended for technically skilled apparel manufacturers

- Best For: Mid-market and enterprise textile businesses with technical expertise

- Biggest Strength: Integrated 2D/3D product development workflow

- Main Concern: Steep learning curve requiring extensive training

- Next Step: Request a demo to evaluate fit for your team

This Optitex review highlights strong suitability for skilled teams requiring precision and underscores the importance of training and resources in maximizing its benefits.