Downtime eats into your bottom line.

For maintenance leaders and facility managers, relying on spreadsheets and outdated systems is more than just frustrating. It means wasted hours, stuck paperwork, and missed preventive tasks that lead to unexpected breakdowns. It is tough to stay ahead when you are always reacting instead of planning.

Inconsistent records and unplanned outages leave you scrambling to catch up. Trust me, you are not alone.

According to MaintainX’s research, organizations leveraging a modern maintenance management system reported a 32% reduction in parts inventory costs and saved 250 hours per year on routine management. That extra time and budget go right back into improving reliability, not just putting out fires.

Switching to the right maintenance management software can transform your entire workflow and help you tackle these pain points with clarity.

That is exactly what this article is for. Here, I am laying out the best ways to streamline your processes, minimize downtime, and get control of your maintenance operations.

In this article, I am going to break down the best maintenance management software available right now and how each one stands out in boosting productivity.

You will discover tools that help you cut costs, increase asset uptime, and finally get the data visibility you need to drive smarter decisions.

Let’s get started.

Quick Summary:

| # | Software | Target Users |

|---|---|---|

| 1 | Limble CMMS ↗ | Maintenance managers optimizing asset lifecycle |

| 2 | UpKeep ↗ | Operations and reliability teams boosting uptime |

| 3 | Fiix ↗ | Teams reducing downtime with predictive tools |

| 4 | eMaint ↗ | Facility managers cutting downtime and costs |

| 5 | MaintainX ↗ | Maintenance managers reducing downtime and costs |

1. Limble CMMS

Is unplanned downtime killing your productivity?

Limble CMMS helps you slash downtime by automating preventive maintenance and simplifying work orders with real-time updates on all assets.

With its centralized work order management, you can assign, track, and complete tasks from anywhere using the mobile app. This reduces wasted time caused by manual follow-ups and ensures your team stays on schedule. You’ll also love the QR code-enabled work request portal that makes submitting maintenance requests easy for everyone on site.

Maintenance isn’t just about fixing problems.

Limble gives you instant dashboards and automated reports so you can monitor key metrics like downtime, costs, and efficiency to make smarter decisions. It’s perfect if you want to optimize your asset lifecycle and maximize ROI.

Plus, its spare parts inventory feature keeps you stocked by tracking inventory in real time and sending auto-alerts before stocks run out. You might also want to see how the best IP Address Management Software can help simplify your network, keeping your equipment running longer and production smoother.

One more thing: Limble helps you stay audit-ready by tracking compliance with safety checks and regulations automatically.

Key features:

Auto-scheduled preventive maintenance tasks: Keep everything on track so you reduce costly unplanned downtime and extend asset life without extra effort.

Real-time work order tracking with a mobile app: Manage and execute maintenance from anywhere, eliminating communication gaps and speeding up task completion.

Comprehensive dashboards and automated reports: Monitor performance, prove ROI, and make data-driven decisions to boost productivity and reduce maintenance costs.

If you’re interested in growing your team’s effectiveness, check out top mentoring software to boost employee growth.

Learn more about Limble CMMS features, pricing, & alternatives →

Verdict:

Limble CMMS stands out as the best maintenance management software for maintenance managers aiming to cut downtime and boost ROI. Its auto-scheduling helped Allagash Brewing reduce unplanned maintenance by 40%, while its audit-ready compliance eased FDA audits for Spectrum Solutions, proving its real impact.

2. UpKeep

Is your maintenance process slowing down operations?

UpKeep offers a mobile-first, AI-powered CMMS that helps you manage work orders efficiently from anywhere.

This means you can streamline maintenance and reliability tasks without depending on pen and paper. Schedule preventive maintenance that triggers automatically using meter readings and IoT data to minimize downtime and save costs.

It truly simplifies your workflow.

You get clear visibility into asset health, helping increase equipment uptime by 40%, extend lifecycles, and make better repair or replacement decisions.

UpKeep’s parts and inventory management ensures you always have the right parts on hand, with automated alerts to prevent stock shortages and optimize purchasing.

Data-driven dashboards reveal KPIs like maintenance compliance, time, costs, and asset reliability so you can make smarter operational choices.

UpKeep combines AI with mobile accessibility to empower maintenance teams and reliability managers to work faster and more effectively. With support available 24/7, and dedicated customer success teams included in their pledge program, you’re not alone after signup.

Key features:

- AI-powered work order management: Quickly create, assign, and track tasks from anywhere, drastically reducing delays and miscommunication.

- Preventive maintenance automation: Schedule and trigger maintenance automatically based on real-time equipment data, lowering downtime and repair costs.

- Comprehensive asset and inventory oversight: Monitor asset health to improve uptime while optimizing part availability with low-stock alerts and streamlined purchasing.

Learn more about UpKeep features, pricing, & alternatives →

Verdict:

UpKeep stands as one of the best maintenance management software solutions for operations and reliability team leaders seeking to cut downtime and boost ROI. For example, Orangetheory Fitness generated over $100,000 in savings by consolidating maintenance requests into one platform. Its AI-powered automation and 24/7 support make it a solid pick for teams eager to improve maintenance visibility and efficiency.

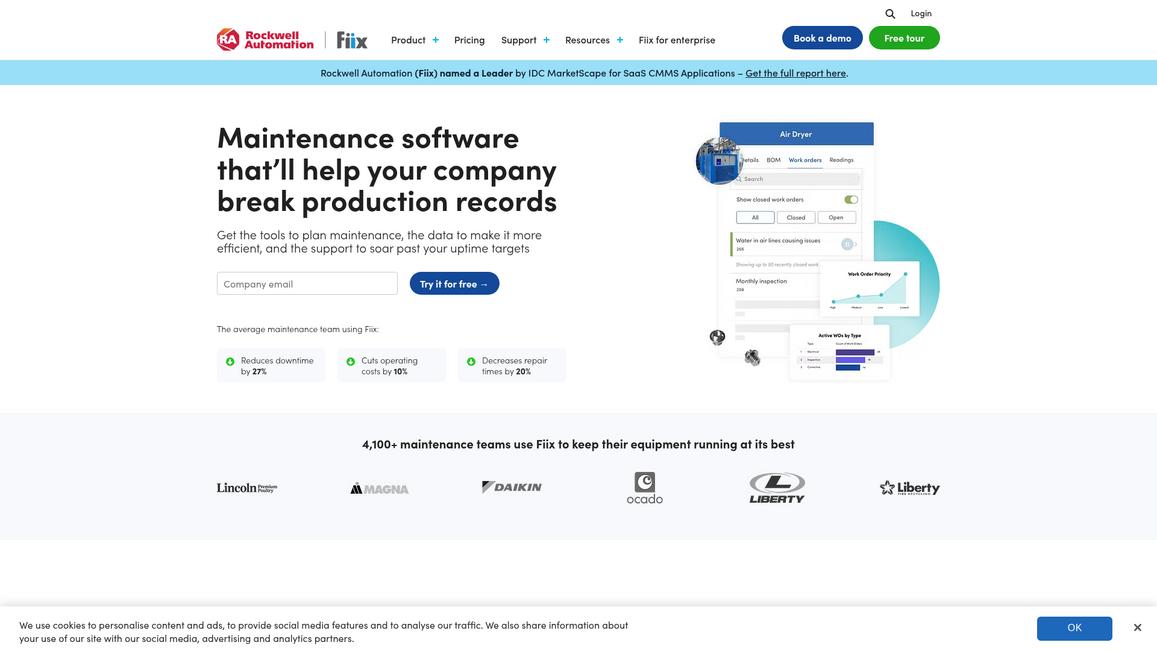

3. Fiix

Struggling with downtime and costly maintenance tasks?

Fiix helps you reduce downtime by 27% with smart tools for maintenance management.

You can easily create, schedule, and prioritize thousands of work orders, freeing your team to focus on repairs instead of paperwork. Its user-friendly interface means you’ll spend less time on admin and more time on wrench time. Fiix’s work order insights highlight issues causing delays, so you fix problems before they escalate.

Maintenance made simple.

Fiix tracks and optimizes asset performance so you’re never guessing when to repair or replace. This means less unexpected failures and smoother production runs.

The software also offers an AI-powered Asset Risk Predictor, letting you predict failures before they happen. That way, you avoid costly shutdowns and unnecessary inspections.

Fiix’s analytics and reporting tools help you spot trends in maintenance data, cutting labor costs by 44% and audit costs by 13%. If security is a concern, you may want to consider using application security tools to reduce risks and secure data. The mobile app helps your team manage work orders anywhere, even offline.

It’s easy to connect Fiix with your existing systems to get data flowing where you need it most.

Key features:

- Work order management made faster. Automate creation, prioritization, and tracking to reduce repair times by 20% and boost technician productivity.

- Asset monitoring and predictive maintenance. Use AI-driven risk predictions to prevent failures and reduce downtime by 27%, keeping production steady.

- Smart inventory control and analytics. Avoid stockouts, cut costs, and leverage data to improve maintenance decisions across your facility.

Learn more about Fiix features, pricing, & alternatives →

Verdict:

Fiix stands out as a top choice for anyone seeking the best maintenance management software. Its combination of automated work orders, predictive AI tools, and insightful analytics helped companies like Perth County Ingredients cut maintenance costs by $40,000 annually. If you want to boost uptime and slash repair times, Fiix might be just what your maintenance team needs.

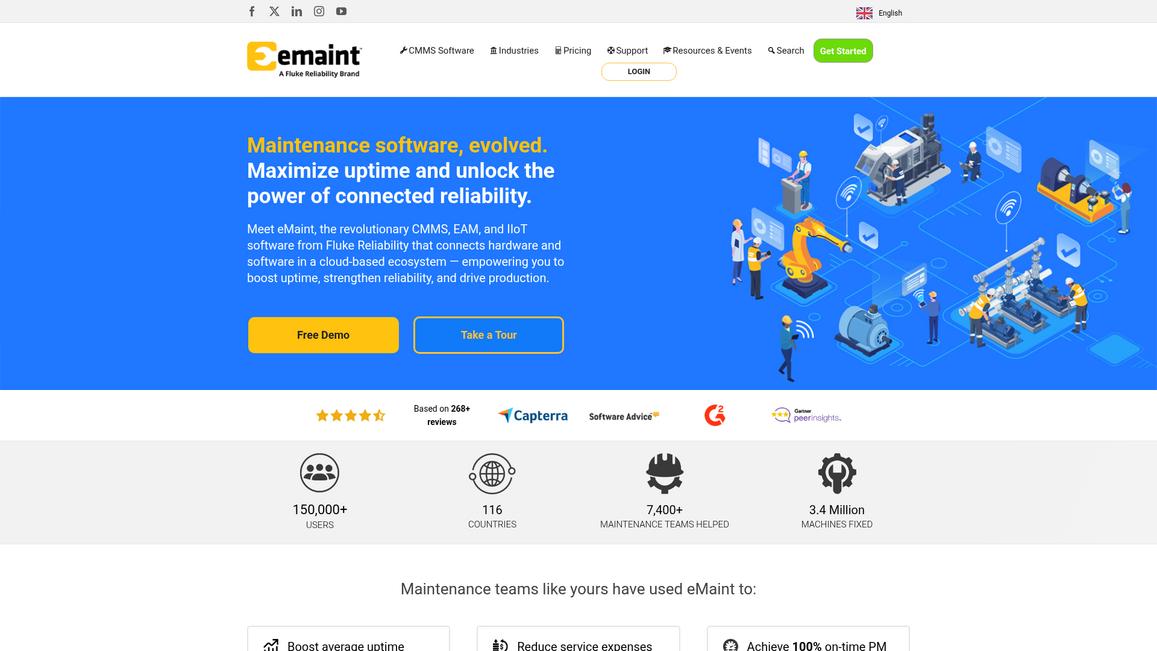

4. eMaint

Worried about costly downtime disrupting your operations?

eMaint offers a powerful CMMS solution that helps you boost uptime and reduce maintenance costs with easy preventive and predictive maintenance tools.

You get an organized asset management system that keeps your equipment info and history just a few clicks away. This helps you extend equipment life and schedule maintenance before issues arise. Its work order management is simple and automated, cutting down on paperwork and saving your maintenance team’s time.

Maintenance made easy.

With a drag-and-drop PM calendar, you can schedule or automate work orders based on real-time asset data. This keeps your maintenance timely and efficient.

Another great capability is how eMaint optimizes spare parts inventory. It ensures that you have critical parts available without overspending on excess stock, so emergencies don’t stall production.

Their reporting tools make tracking KPIs and audit compliance straightforward, even if you’re not a data expert. This helps with decision-making and regulatory needs alike.

eMaint connects to Fluke sensors and integrates with 1000+ apps, bringing live condition monitoring straight to your dashboard.

Key features:

- Extensive asset management system: Track assets in a structured hierarchy with full status and maintenance history to optimize their lifespan and reduce unexpected failures.

- Automated and easy work orders: Create, schedule, and manage work orders effortlessly with drag-and-drop calendars and automated triggers based on sensor data.

- Spare parts inventory optimization: Maintain critical spare parts availability while avoiding excess inventory to balance emergency readiness and cost control.

Learn more about eMaint features, pricing, & alternatives →

Verdict:

eMaint stands out as the best maintenance management software for facility and maintenance managers aiming to cut downtime and cut operational costs. Backed by success stories like Advanced Atomization’s uptime boost to 95%, and Jack Daniel Cooperage’s near-perfect PM completion, it’s a proven tool for maximizing asset reliability and team efficiency.

5. MaintainX

Looking to cut costly unplanned downtime?

MaintainX helps you create, assign, and track work orders effortlessly, so your team manages maintenance work more efficiently and avoids surprises.

This software lets you automate preventive maintenance, reducing unexpected breakdowns by 32%. It uses real-time data from IoT sensors to trigger condition-based work orders automatically, which means less downtime and better asset reliability. Plus, you get customizable dashboards and reports that turn data into actionable insights, helping you optimize costs and operations.

Maintenance doesn’t have to be chaotic.

You can enforce safety procedures with digital inspections and checklists, which helps you stay compliant with OSHA and EPA regulations without the hassle.

Another strong point is parts inventory management. MaintainX monitors your stock, alerts you when supplies run low, and automates reordering, helping you reduce parts spending by up to 34%.

Simple to use, MaintainX also enhances collaboration across teams and sites while offering enterprise-grade security and control.

Key features:

- Automated preventive and predictive maintenance to reduce downtime by scheduling repeatable tasks and triggering work orders from IoT sensor data.

- Comprehensive parts inventory management that alerts you on low stock and automates reorders, cutting emergency shipping costs and inventory waste.

- Safety and compliance automation with digital checklists and inspection tracking, ensuring consistency and avoiding regulatory fines.

Learn more about MaintainX features, pricing, & alternatives →

Verdict:

MaintainX stands out as the best maintenance management software for facility and maintenance managers who want to reduce downtime and control costs. With proven results like a 33% decrease in unplanned downtime for Titan America and $50K+ savings on parts inventory, it clearly helps teams work smarter and safer.

Conclusion

Are you tired of unplanned downtime?

As a facility manager, facing constant unexpected breakdowns can be incredibly frustrating. It not only disrupts operations but also drains resources and impacts your bottom line. Without effective maintenance management, it’s easy to feel overwhelmed.

In fact, research from MaintainX found that organizations embracing modern maintenance systems achieved a 32% reduction in parts inventory costs and saved 250 hours per year. This freeing up of time and cost demonstrates how crucial it is to make a change.

Choosing the right maintenance management software can really improve your workflow and help tackle these persistent challenges. That’s where Limble CMMS shines. This software automates preventive maintenance and gives you real-time updates on your assets.

By incorporating Limble CMMS, one user reported a swift reduction in unplanned downtime by 40%. It’s time to simplify your processes. I encourage you to book a free demo of Limble CMMS and start transforming your maintenance operations today.

Taking action can lead to considerable efficiency and cost savings in your organization!